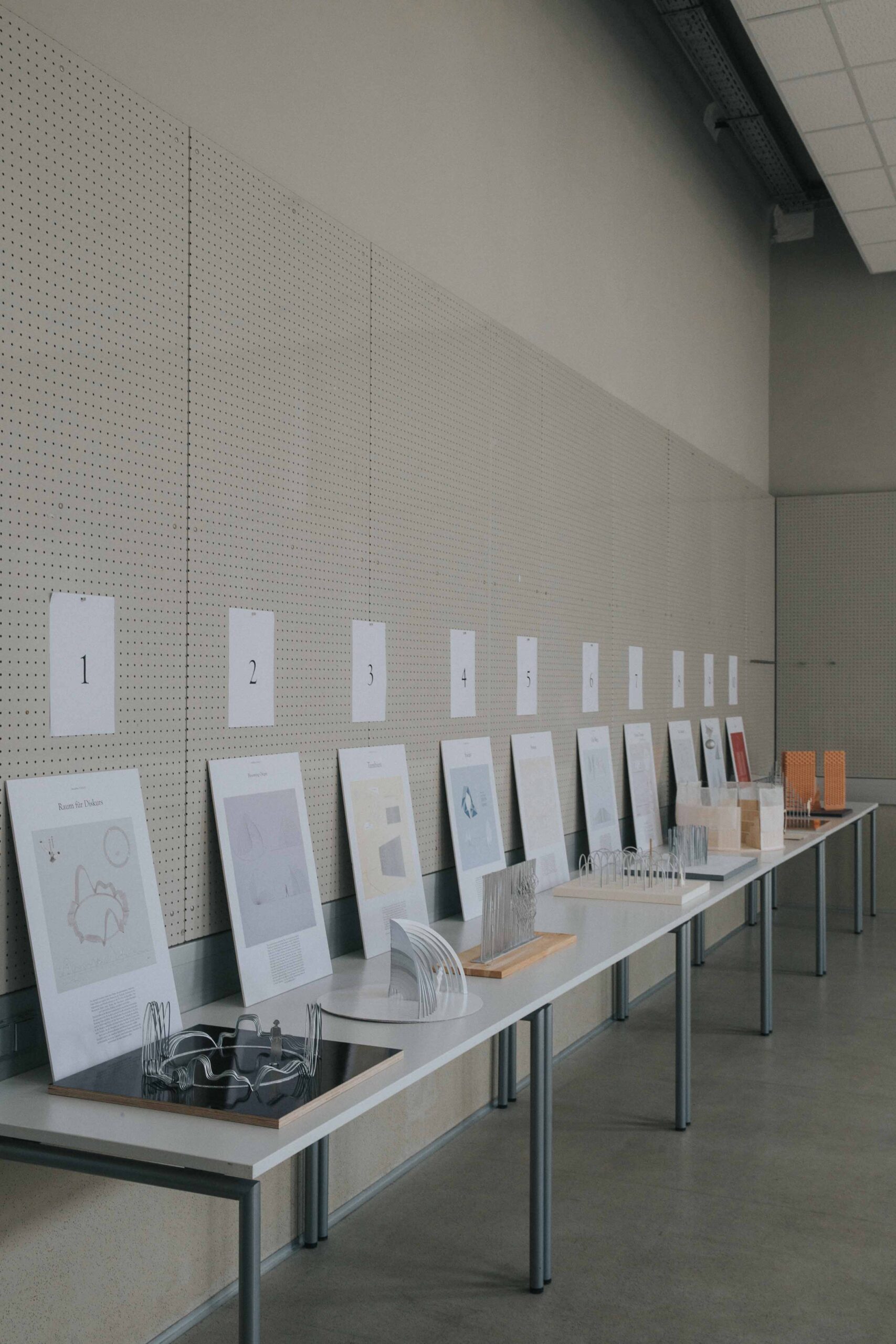

As an important aspect of teaching at the KOEN Institute is the analogue architectural model as a design medium, the renovation of Kronesgasse also led to a restructuring and the organizational assignment of the Architectural Model Workshop of the Faculty of Architecture to this institute. The various construction and design-oriented courses in the first and second semesters were supplemented with elective courses for Bachelor's and Master's students, in which the basics of creating analog models are taught, working with models is trained and new perspectives are shown. The possibilities range from classic craftsmanship to the digital production of conceptual considerations and presentation models.

As an important aspect of teaching at the KOEN Institute is the analogue architectural model as a design medium, the renovation of Kronesgasse also led to a restructuring and the organizational assignment of the Architectural Model Workshop of the Faculty of Architecture to this institute. The various construction and design-oriented courses in the first and second semesters were supplemented with elective courses for Bachelor's and Master's students, in which the basics of creating analog models are taught, working with models is trained and new perspectives are shown. The possibilities range from classic craftsmanship to the digital production of conceptual considerations and presentation models.